If the hazard had been seen, he wouldn’t have gotten hurt…

A few years ago, I was working with a large global manufacturer. They had experienced a rash of incidents that had resulted in their injury rate jumping to a level they hadn’t seen in a decade. Executives were all over it – therefore, so was everyone else! I recall asking a small group of leaders one simple question ‘Do you think the things that caused these incidents suddenly appeared in the last six months, or that they were there all along but didn’t rise to the surface because no one got hurt?’ (The question is a little self-serving, of course we know the answer.) The real question is ‘why weren’t these hazards identified before they caused someone to get hurt?’

John had been with his company for 22 years. He had worked in a number of areas of the plant and had been in maintenance for a while, but for the last 3 years he had been working on a part of the line that fed pellets into a large grinder. John was always a little frustrated with the job. The original install wasn’t done very well and the feed conveyor was inclined to jam as the pellets entered the grinder. He had put in several requests to maintenance for a fix, but nothing had been done. When the conveyor feed jammed the easiest solution was to use a piece of dowel to release the blockage. Yes, turning off the grinder was probably ideal but it took way too long. One morning John was going about his usual duties when the conveyor jammed. So, he did what he always did. But, on this particular morning the pellets had gotten compacted so he had to push harder than usual. The blockage suddenly gave way and John fell towards the grinder. He instinctively put out his hand to stop himself from falling and his arm was drawn into the grinder……he had the presence of mind to hit the shutdown just before he passed out.

The incident investigation discovered a curious thing. At no time in the previous three years had an audit identified the problem. All the more curious was the fact that on a wall alongside the grinder were about a dozen pieces of dowel with teeth marks on them. Clearly there are many questions to be asked here, such as why corrective action wasn’t taken earlier? But the one big question the investigating team asked was why this hadn’t been seen before when the issues were so obvious and plain to see?

Slowing Down and Seeing What’s in Front of You

Susan had been driving the same route to work every weekday for five years. It was a pleasant rural route and she liked that she wasn’t sitting on a busy freeway. She knew the route like the back of her hand – the long sweeping corner by the farm, the crest of the hill before the road dived down into the river valley, the bridge over a small creek with a sharp left-hand turn after it. This one particular morning it was frosty, Susan noticed as she approached the bridge that the road surface was shiny, the sun reflecting off it like a mirror. Something made her lift off the gas. As she started across the bridge her steering went lose. It was then she realized what the ‘shiny’ was – ice! By good fortune, she was going slowly enough, and the patch was small enough, that she got little more than a fright and was able to navigate the left-hand turn. As she drove on, she thought to herself ‘what if I hadn’t seen that shiny surface?!’

Whether in work, or in life, our ability to identify things that might hurt us is about as basic a form of human cognition as any. Our very survival depended on it throughout history. So much so that a significant proportion of our brain and eyes function automatically. Filtering and sorting vast amounts of data in milliseconds so we are able to not only survive, but function and get things done at work or play. This preprogramming serves us well most of the time, but then sometimes it doesn’t. Have you ever driven through a stop light that you could swear wasn’t red?

Identifying hazards is fundamental to how we manage risk in the workplace. And yet, our eyes and brain often conspire in such a way as to allow us to miss critical information. That’s how we are designed. So, helping overcome these gaps is central to ensuring we have our people focused on hazard identification.

Applications of Visual Literacy in Industry

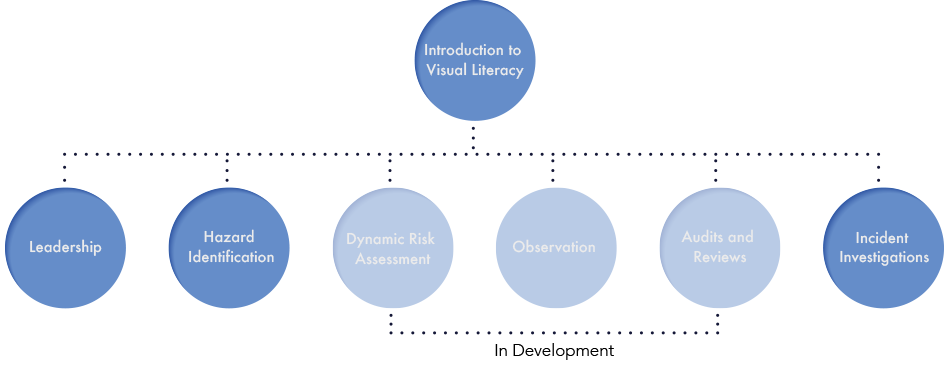

At COVE we have developed a series of modules to help train workers, safety professionals, supervisors and leaders in the techniques of Visual Literacy, providing structured processes to alleviate gaps in visual acuity. Across the gamut of safety critical activities we know that accurately observing, assessing, evaluating and communicating what we see, is essential if our safety programs are to function as intended. The modules help participants approach ‘seeing’ with a process, framework, discipline and set of skills proven to enhance accuracy, depth, analysis and evaluation of the physical environment, and human interaction with it. In doing so, more hazards are identified, better understood, risks assessed and suitable corrective and preventive actions can be taken.

Whether your challenges are thorough safety audits, ensuring complete hazard assessment pre-task, dealing with upset or non-routine conditions, safety observations or assuring incident investigations are conducted to the highest possible standard, COVE’s Visual Literacy training can be integrated into your existing programs.